Completely rehabilitating a 115-year-old tunnel is a massive undertaking. During the decommissioning phase earlier this summer, we removed approximately 24,000 linear feet of running rail, 12,000 linear feet of 3rd rail, 8,000 railroad ties, and 8,000 cubic yards of ballast.

Now in the bench wall demolition phase, the team is working to remove approximately 24,000 linear feet of bench wall along the entirety of the three-mile-long tunnel.

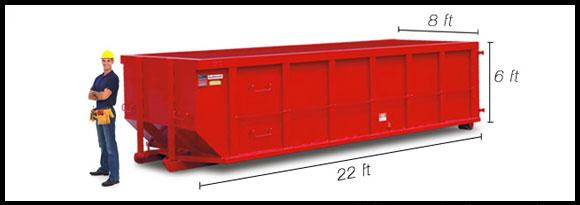

With 20,000 cubic yards of concrete, that’s equivalent to demolishing and removing upwards of 650 fully packed construction dumpsters (pictured on right).

The extreme age, density, and composition of the concrete make the demolition process quite complex. It’s not like knocking down drywall with a hammer for a home renovation! The bench walls were built to last more than a century, featuring concrete, rebar, terracotta conduits, cables, diamond plates, and steel installed at splice chambers.

To advance this intense work, our contractor has deployed Brokk robotic demolition machines at six active locations throughout the tunnel, supported by hydraulic rock splitters. The Brokk is a versatile machine often used for precision demolition in tight spaces, featuring a rubber-wheeled design that improves mobility while keeping operators at a safe distance from falling debris.

Outside the tunnel, work continues for a future Aerial Utility Bridge, which will transport signal and traction power cables across the east portal of the tunnels (from Line 2 over Line 1 and the Long Island Rail Road tracks). Significant progress has also been made on duct bank installation along Line 1 at Skillman Avenue, as pictured below. All this work brings us one step closer to setting the utility bridge in place and installing a new signal hut later this fall.

This Website Uses Cookies

Amtrak New Era uses cookies and other tracking technologies to enhance your experience, provide personalized content and ads, and analyze our traffic. These cookies may be set by us or by third-party partners. Non-essential cookies will only be used if you give your consent. You can manage your preferences at any time through the Cookie Settings link. If you are a California resident, you have the right to opt out of the sale or sharing of your personal information. Selecting "Decline All" will opt you out of non-essential cookies and any such data sharing. To learn more, please see our Privacy Policy.